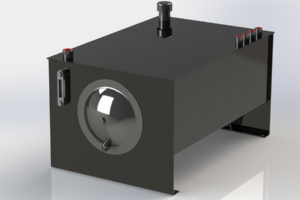

Standard Technologies is fully equipped to manufacture and meet all of your hydraulic fluid reservoir requirements.

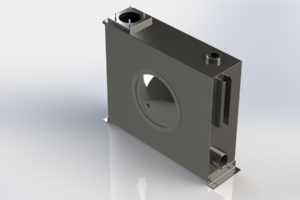

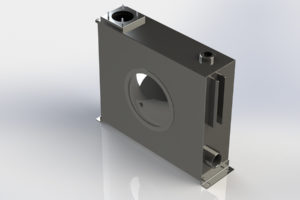

Among our diverse array of custom fabrication and industrial manufacturing solutions, Standard Technologies is a leading manufacturer of hydraulic reservoirs for both mobile and industrial applications. From one-off, complex designs to standard-sized models, we work closely with our customers to ensure they always receive the quality products they expect.

Drawing from a variety of materials, including steel, stainless steel, aluminum, and aluminized steel, our team can assist in designing a hydraulic reservoir tailored to your specific application. Our established relationships with component manufacturers allow us to build and assemble complete systems — not just the weldment —, and we will work with your design team and procurement departments to ensure cost-effectiveness at every stage.

Combining the latest software and equipment technology with decades of experience, our engineering and production teams manufacture high quality products based on customer specifications. All of our products are made in a state-of-the-art ISO 9001:2015 facility with documented procedures and certified personnel. Before delivery, every hydraulic reservoir is leak-tested using a non-destructive tracer gas and a top-of-the-line detection system unmatched by our competitors.

Our hydraulic reservoirs serve a range of industries including:

- Agriculture

- Construction

- Defense

- Energy

- Food processing

- Machine tool

- Marine

- Metals

- Mining

- Rail

Mobile hydraulic reservoir equipment is frequently used for:

- Off-road construction equipment

- Post drivers

- Power swivels

- Refuse trucks

- Snow plows

- Underground mining equipment

Industrial hydraulic reservoirs are typically utilized in:

- Material forming equipment

- Security barriers

- Trash compactors

- Test stands

Standard Technologies is your one-stop shop for production. We also offer CNC laser cutting, material forming, robotic welding, powder coating, and a number of other services to complete your project entirely in-house.

Because we can perform all of our manufacturing processes in-house, our team maintains complete control over lead time, cost, and quality to ensure that we deliver our customers the best product with every order. We are fully equipped to manufacture high- and low-volume orders, as well as to prototype new parts. Our ISO 9001:2015 quality standards position us to meet the process-controlled specifications that our clients demand. To learn more, contact Standard Technologies today.