Standard Technologies offers complete custom metal fabrication services, including laser cutting, material forming, welding, and powder coating.

As a full-service, ISO 9001:2015 contract metal manufacturer, we can accommodate a wide array of contract metal fabrication projects from start to finish.

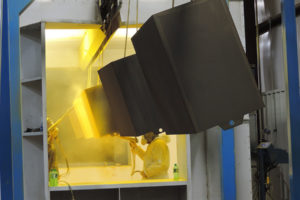

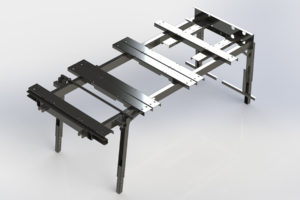

Prior to production, our engineering team evaluates various methods of parts fabrication according to your exact specifications, thereby avoiding the need for costly custom tooling. Our facilities are equipped to handle a variety of materials, including carbon steel, stainless steel, and aluminum. For stainless steel custom metal fabrication, we ensure precise and efficient processes. We also have in-house finishing services for a range of coating requirements that include powder coating and plastisol.

Committed to equipping our facilities with the latest technology and machinery, our team utilizes advanced manufacturing and engineering software to efficiently manufacture within our customers’ specifications.

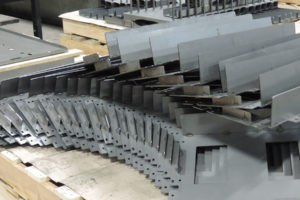

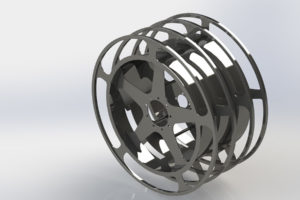

Combining decades of operator experience with advanced machinery and equipment, we can provide a wide spectrum of precision capabilities for complex parts. Standard Technologies offers a range of welding services, including automated robotic welding for consistent and rapid precision welding work. Our laser cutting projects are conducted on an automated CNC laser, and all of our material bending, rolling, and forming work can be completed in-house.

We have the experience and capacity to accommodate orders from single prototypes to high-volume orders. Our wide spectrum of advanced in-house capabilities allows us the autonomy to control every aspect of each order from the moment we receive the order until shipping. This advantage ensures that our customers always receive high-quality, cost-competitive products on time.

Industries We Serve

At Standard Technologies, we understand that each industry has unique demands, and our expertise in precision outsourcing custom metal fabrication allows us to deliver solutions tailored to meet those specific requirements. We are proud to support a wide array of industries with high-quality, durable products that stand up to the toughest conditions. Whether you’re in agriculture, construction, energy, or transportation, our team ensures every project is completed with precision and customization at its core.

- Agriculture & Construction: We make components like fuel tanks, hydraulic reservoirs, and metal enclosures for backhoes, dump trucks, and mining vehicles, ensuring reliable operation in rugged conditions.

- Commercial & Transportation: Our custom metal fabrication supports vehicles from buses to industrial utility trucks, with an emphasis on safety and efficiency.

- Energy: We provide precision-engineered parts for wind, solar, and oil industries, ensuring long-lasting performance.

- Recreational Vehicles: We produce custom components for trailers, campers, and motor coaches, built for both durability and aesthetic appeal.

No matter the industry, our focus is on providing precise, durable, high-quality custom metal fabrication. Our expertise extends to fabricating fuel tanks, hydraulic reservoirs, battery trays, and metal enclosures, ensuring that your project is completed to precise and the highest standard.

Expect the Best with Standard Technologies

If you are looking for a reliable partner for your custom metal fabrication needs, look no further than Standard Technologies. Our contract metal fabrication makes us the ideal choice for your projects. Contact us today to discuss how we can help you achieve your manufacturing goals with precision and efficiency.