Standard Technologies leads the industry in powder coating services, utilizing extensive expertise to fulfill the diverse requirements of various sectors. Our specialized industrial powder coating services highlight the numerous advantages of industrial powder coating compared to traditional wet paint options. By providing exceptional quality and innovative solutions, we assist businesses in enhancing their products’ aesthetics and durability.

The Process

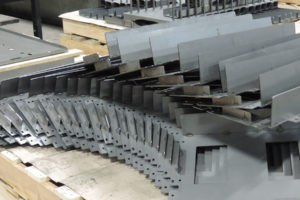

Our powder coating pre-treatment processes include media blasting and a 5-stage wash system to produce a material substrate essential to the longevity and performance of the finished coating. Once the pre-treatment process is complete, we dry and preheat the parts for powder coat application.

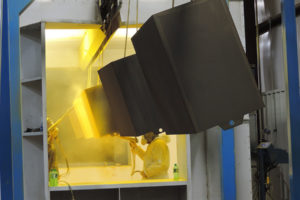

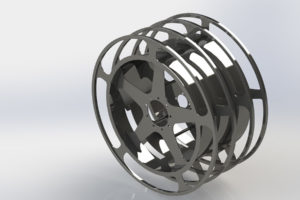

As part of our industrial powder coating services, customers can choose from a variety of colors for the very fine dry resin particles that comprise the powder. Using a spray gun, we apply this resin powder with an electrostatically charged technique that causes the particles to stick to the grounded part through the curing process—just like metal to a magnet.

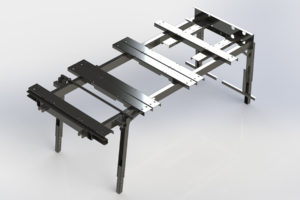

We then heat the coated parts to specific temperatures for a predetermined amount of time based on the chemistry of the powder resins and the density of the coated part. The powders melt and fuse together to form a durable finish. Not only can we efficiently coat high-volume parts with our continuous powder coat line, but we can also coat some of the largest weldments utilizing our industrial batch oven.

When extreme environments require a more robust coating, we offer plastisol, a liquid PVC coating that is baked onto the surface of your steel product. This coating provides superior protection against impact and harsh chemicals, as well as excellent dielectric strength. By using a spray-on method, we can coat large and heavy parts where dip coating would not be feasible.

Advantages to Powder Coating

Our powder coating services provide our clients’ parts with:

- Durability — We can formulate various chemistries to endure the severity of harsh chemicals, abrasion, or UV exposure.

- Variety — Powder coatings are available in a wide array of colors, textures, and glosses.

- Quality — Our process is continuous and almost fully automated, which eliminates defects caused by dust or corrosion build-up between the pretreatment and powder coating phases.

- Environmental Friendliness — As a part of our company policy, there are no volatile organic compounds (VOCs), a major cause of air pollution, involved in any part of our industrial powder coating process.

Quality Control and Environmental Responsibility

We hold ISO 9001:2015 certification, reflecting our dedication to maintaining high standards across all aspects of our powder coating services. Our automated processes enhance efficiency and consistency, ensuring that each project adheres to rigorous quality controls from start to finish.

In addition, we emphasize environmental responsibility in our operations. Our industrial powder coating processes generate no volatile organic compounds (VOCs), presenting an eco-friendly alternative to traditional wet paint solutions. This commitment to sustainability aligns with businesses aiming to reduce their environmental impact while achieving high-quality finishes.

Get Coated in Quality with Standard Technologies

Our dedication to excellence, innovative methods, and environmentally responsible practices set us apart in the industry. If you seek to enhance your products with our powder coating services, we encourage you to contact us. Together, we can explore how our industrial powder coating services can fulfill your specific needs and elevate your products to new heights.